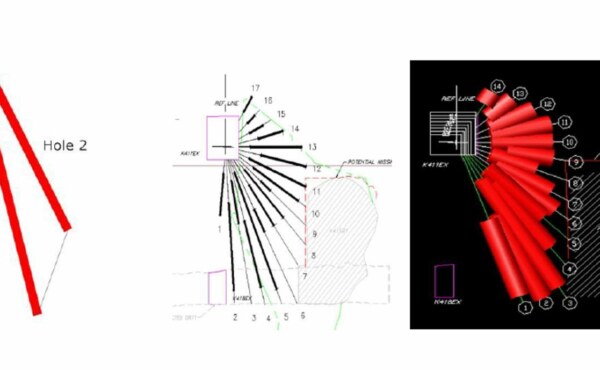

Underground blasting operations are challenging from the standpoint of the distribution of explosives energy representative of ring blasting. Energy from both shock and pressure regimes of commercial explosives may appear concentrated in the collar region of a typical ring blast and diluted at the toes of holes due to the oblique geometries of blastholes. The non-homogenous nature of ore in which explosives are distributed via drillholes, adds to the complexities of generating particulate profiles from fragmented material with consistencies that are predictable from blast pattern to blast pattern – well suited for specific underground handling equipment and mill processing. In an ideal world, it would be the blasting operations themselves that represent the primary crushing mechanism, or at least mitigate mechanical crushing that can comprise a large component of the cost in generating suitable muck. This paper presents a dynamic break view in 3D that allows a planner to visualize the potential break zone around a blasthole generated by an explosive load using a Kleine field. Simple as it sounds, this methodology provides information that can be used in conjunction with cavity monitoring surveys (CMS) to potentially judge dilution due to overbreak as well as recovery for a typical blast. As examples, there are two break geometries that are examined regarding circular breaks and elliptical breaks around blastholes. Using a Kleine field to define break, a planner generated isosurface can be generated and compared to CMS data for calibration and prediction, using AEGIS 3D ring design software.

Author: Chris Preston, Troy Williams and Ian Lipchak

Link to download.