Orica was presented with the 390L WEZ 49A block in July 2020. While the block size was typical for a Borden WebGen™ stope, the complexity lied in the geometry. Due to varying stages of completion in the development drifts surrounding the stope, successful extraction would need to be accomplished via drilling on 4 separate horizons, at a multitude of angles. The drilling would consist of a combination of up-holes, down-holes and side-holes from the 390 and 375 levels.

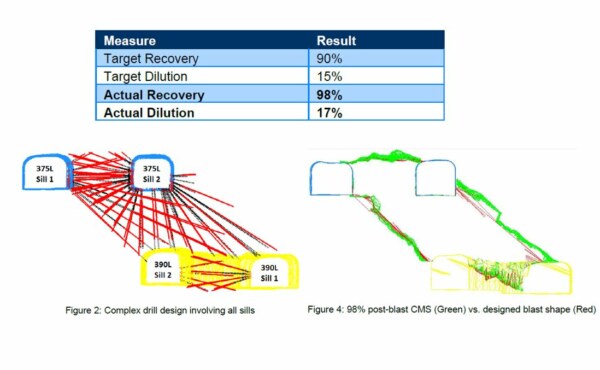

Once the stope reconciliation was completed this stope’s performance was evaluated as an exemplary success. With targeted recovery of 90% and 15% dilution, the efforts put forth by Newmont, Orica and Redpath resulted in a 98% recovery and 17% dilution. The additional dilution was due to slight overbreak in the hanging wall along a joint set, which is typical of Borden. Minimal broken muck was left sitting on the footwall despite its 43-degree angle, thanks to the enhanced timing and sequencing capabilities of WebGenTM 100. Case study by Orica.

Follow the link to dowload the case study.

Case study_Newmont Borden Case Study -Optimising Complex Stope Designs